Preload is the force applied in advance to enhance the reliability and tightness of the connection before the load is applied, so as to prevent the gap or relative slip between the connectors after the load is applied.

一、Product overview

Preload is the force applied in advance to enhance the reliability and tightness of the connection before the load is applied, so as to prevent the gap or relative slip between the connectors after the load is applied.

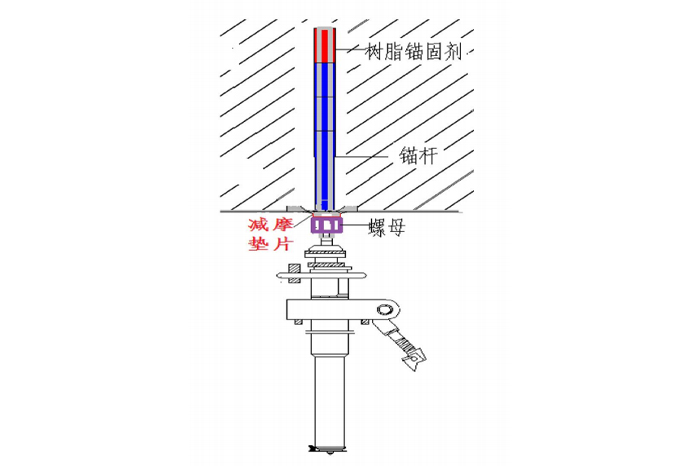

The preload of bolt mainly refers to the torque applied to bolt by nut after the installation of bolt in construction to meet the design requirements, so as to realize the real active support. In the process of roadway excavation, in order to prevent sheet and roof collapse, the roof and two sides will be driven into the rock bolt, in order to strengthen the rock layer, in order to test whether the reinforcement is qualified, and the rock bolt into the rock is firm, will use torque wrench to screw the nut, in order to measure the preload of the bolt.

二、Product structure

The hollow grouting anchor cable is used as the permanent support of surrounding rock, the advance support of highway, railway and tunnel, slope protection, foundation pit support, and the support and reinforcement of mine roadway, blockchamber and crossover points.

三、Product characteristics

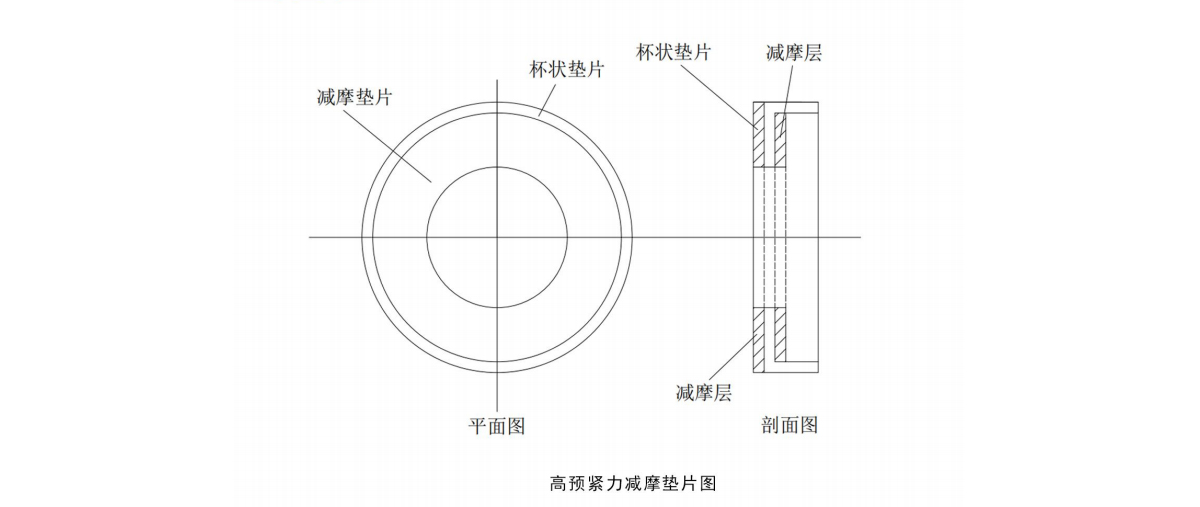

The high preload antifriction gasket can make the bolt produce high preload on the surrounding rock of the roadway, and has good effect on the roadway, roadway repair and roadway reinforcement with high driving pressure. The bolt body and the surrounding rock form an organic whole, which has simple structure, high stability, reasonable design, simple operation and low labor intensity.

The product is directly installed between the ordinary bolt nut and the tray, without changing the existing installation process. The pre-tightening bolt can be directly installed through the bolt drill, and the pre-tightening force can be increased by 2-3 times without the need for secondary pre-tightening, and will not cause damage to the tail of the bolt.

四、Construction method

When installing the bolt, add the preload antifriction gasket between the preload nut and the gasket plate, antifriction gasket plane against the gasket plate, antifriction layer against the preload nut, when the bolt machine rotates, the nut contact antifriction layer, due to the friction layer is minimal, the nut is rapidly preload, the preload force is 2-3 times of the friction gasket without adding or reducing. The research shows that under the same torque, the smaller the friction between nut and gasket, the greater the preload of nut. The friction between nuts and gaskets consumes 85 -90% of the bolt machine torque.

The use of concrete accelerator

2022-12-101. Concrete accelerator is a kind of surface active material, added to concrete, cement particles play a diffusion effect…What should we pay attention to when constructing powder accelerator?

2022-12-101. Raw materials: Quality shall meet JC476-1998 standards, cement shall be qualified and unexpired Grade 32.5 (original 4…What are the commonly used support and reinforcement technical measures outside the dug tunnel

2022-12-10Shoting-anchor excavation method refers to the construction method of tunnel construction by excavation of underground tu…